Asphalt Recycling

Recycling asphalt isn’t just about reusing materials—it’s about doing it right. Falcon’s innovative technology protects the integrity of the original asphalt, providing a cost-effective and sustainable solution for year-round repairs. Ready to repair smarter and more efficiently?

Asphalt Recycling Demonstration

How the Asphalt Recycling Process Works

Falcon’s patented technology utilizes indirect, radiant heat to break down hardened asphalt, chunks, and millings. Unlike older recycling methods that apply an open flame—burning off essential oils and creating dry, brittle asphalt—Falcon’s system ensures asphalt is restored to its optimal state.

Here’s how it works:

- Hardened asphalt is coated with a rejuvenator during the hopper loading process.

- The material is then heated overnight at the lowest possible temperature, allowing the rejuvenator to absorb fully.

- This process preserves the original oils, maintaining the recycled asphalt’s workability and durability.

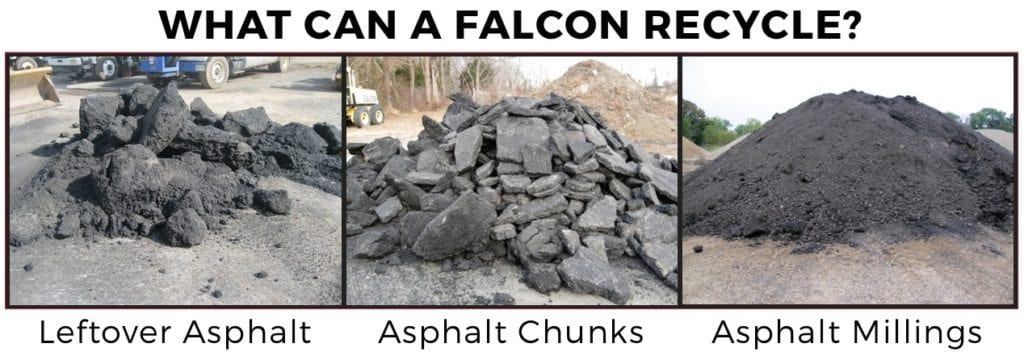

What Types of Asphalt Can a Falcon Recycle?

Falcon’s asphalt recyclers can handle:

-

- Leftover asphalt from previous jobs

- Asphalt chunks and millings

- Hardened asphalt in need of rejuvenation

Why Should You Recycle Asphalt?

Recycling asphalt pavement isn’t just a smart choice—it’s a strategic one. By recycling leftover asphalt, you can:

-

- Make permanent hot mix repairs year-round and avoid temporary cold patch fixes.

- Reduce trips to the asphalt plant, cutting down on travel time and wait times.

- Secure on-site access to hot mix asphalt whenever you need it, without the hassle of plant schedules.

Why Recycle Asphalt Overnight?

-

- Preserve original oils – Slow, low-temperature heating gives the rejuvenator time to fully absorb, restoring the asphalt’s properties.

- Maximize productivity – Recycled asphalt is ready at the start of the workday, allowing crews to focus on repairs instead of prep work.

- Simplify the process – Just coat the hardened asphalt with a rejuvenator during loading, and the Falcon system does the rest.

The Falcon Advantage: Why Our Equipment Stands Out

We Protect the Original Oils

-

- Indirect, radiant heat maintains asphalt integrity at the lowest effective temperature.

- This process ensures asphalt remains workable without becoming brittle or dry.

We Use Heat More Effectively

-

- 92% fuel efficiency thanks to Falcon’s optimized combustion chamber design.

- High-density insulation retains heat, making the recycling process more efficient.

- Strategic heat distribution with an upper burner and cross ducts delivers even heating.

We Build Equipment That Lasts

-

- Heat management components withstand extreme recycling temperatures.

- Reinforced hoppers handle heavy asphalt chunks without damage.

- Durable construction supports long-term performance, even in tough conditions.

Trust Falcon Asphalt Recycling Equipment

Falcon’s hot boxes and asphalt recyclers offer unmatched efficiency, durability, and cost savings. Whether you’re looking to reduce waste, lower costs, or increase productivity, our equipment is designed to keep your asphalt in prime condition for high-quality repairs.

The MiDEAL Advantage

The MiDEAL Extended Purchasing Program provides opportunities for members to leverage the contracts established by the State of Michigan.

Contact

2600 W Salzburg Rd

Freeland, MI 48623

Phone: (989) 495-9332

Fax: (989) 495-9342

Sales:

(989) 495-9332

Service:

(989) 495-9332